BRC B9 Wire Mesh – High-Quality Reinforcement Mesh 🏗️

BRC B9 Wire Mesh – High-Quality Reinforcement Mesh 🏗️

📌 What is BRC B9 Wire Mesh?

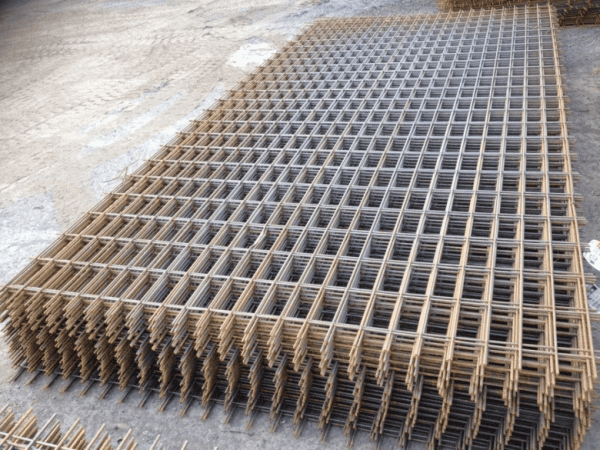

BRC B9 wire mesh is a premium-grade steel reinforcement fabric designed to enhance concrete strength and durability. Manufactured under BS 4483 standards, it ensures consistent quality, stability, and ease of installation for various structural applications.

This pre-welded steel mesh reduces labor time, enhances load distribution, and provides crack resistance, making it an essential component in civil, commercial, and residential construction projects.

📐 BRC B9 Wire Mesh Specifications

✅ Fabric Ref. No.: B9

✅ Standard Reference: BS 4483

✅ Main Wire Diameter: 9mm

✅ Cross Wire Diameter: 9mm

✅ Main Wire Spacing: 100mm

✅ Cross Wire Spacing: 200mm

✅ Cross-Sectional Area (Main/Cross Wire): 642mm²/m & 321mm²/m

✅ Mass Per Unit Area: 6.97 kg/m²

✅ Standard Sheet Size: 2.2m x 6m

✅ Mass Per Sheet: 92 kg

🔄 BRC BS vs. CQ Wire Mesh – Key Differences

BRC wire mesh is available in two main types: BS (British Standard) and CQ (Commercial Quality).

- BS Wire Mesh ✅ – Cohttps://buildmatehardware.com.my/product/brc-a9-bs-2-2m-x-6m-x-8-5mm-non-jkr-common-spec/mplies with British Standards, making it suitable for structural reinforcement and load-bearing applications.

- CQ Wire Mesh ⚠️ – Lower-grade wire mesh used for non-structural applications like fencing and partitions.

If you need high-strength and durable reinforcement, BS wire mesh is the best choice for construction projects.

🏗️ Where to Use BRC B9 Wire Mesh?

🔹 Reinforced concrete slabs & foundations – Provides enhanced structural stability.

🔹 Highway and road pavements – Distributes load evenly to prevent cracking.

🔹 Precast concrete products – Used in prefabricated panels and structures.

🔹 Tunnel linings & bridges – Adds reinforcement in critical infrastructure.

🔹 Warehouse & industrial flooring – Withstands heavy loads and impact.

🔹 Multi-story building structures – Ensures strong concrete reinforcement.

🔍 People Also Ask (Q&A):

1️⃣ What is the difference between BRC B9 and B10 wire mesh? – has 9mm diameter wires, while B10 uses 10mm wires, offering greater strength.

2️⃣ How do you calculate BRC B9 wire mesh weight? – Multiply the mass per unit area (6.97 kg/m²) by the total square meters needed.

3️⃣ Where can I buy BRC B9 wire mesh? – It is available at construction material suppliers, hardware stores, and online platforms.

4️⃣ What are the advantages of BRC B9 wire mesh? – It provides high strength, cost efficiency, quick installation, and uniform reinforcement.

5️⃣ What is the standard size of BRC B9 wire mesh? – The most common size is 2.2m x 6m, perfect for various structural applications.

6️⃣ Is BRC wire mesh corrosion-resistant? – Standard BRC mesh is not rust-proof, but galvanized versions offer enhanced durability.

7️⃣ Can BRC B9 wire mesh be used for bridges? – Yes, it is widely used in bridge decks, tunnels, and other infrastructure projects.

8️⃣ Why is BRC wire mesh used in concrete reinforcement? – It prevents cracking, enhances tensile strength, and improves load distribution.

9️⃣ What factors should I consider when choosing BRC wire mesh? – Look at wire diameter, spacing, sheet size, and compliance with BS standards.

🔟 How is BRC wire mesh installed? – It is laid onto reinforced concrete structures and secured with steel ties or rebar supports.

📌 Why Choose BRC B9 Wire Mesh?

✅ Durable & High Strength – Designed for heavy-duty structural applications. ✅ BS 4483 Certified – Meets engineering and safety standards. ✅ Pre-Fabricated for Easy Installation – Reduces labor costs & project time. ✅ Versatile & Cost-Effective – Suitable for multiple construction uses. ✅ Crack-Resistant – Improves long-term concrete performance.

💲 Get the Best Price for BRC Wire Mesh!

Looking for high-quality BRC B9 wire mesh at the best price? Contact us today for a quote! 📞💬